Innovations in battery technology are critical to clean tech future

Advancements in battery technology are increasingly focused on developing clean tech solutions. Improved battery manufacturing processes reduce reliance on scarce raw materials and enhance recyclability of existing batteries.

Note: The views expressed here are solely those of the author and/or interview subject and do not represent positions of IEEE.

Battery technology has emerged as a critical component in the new energy transition. As the world seeks more sustainable energy solutions, advancements in battery technology are transforming electric transportation, renewable energy integration, and grid resilience.

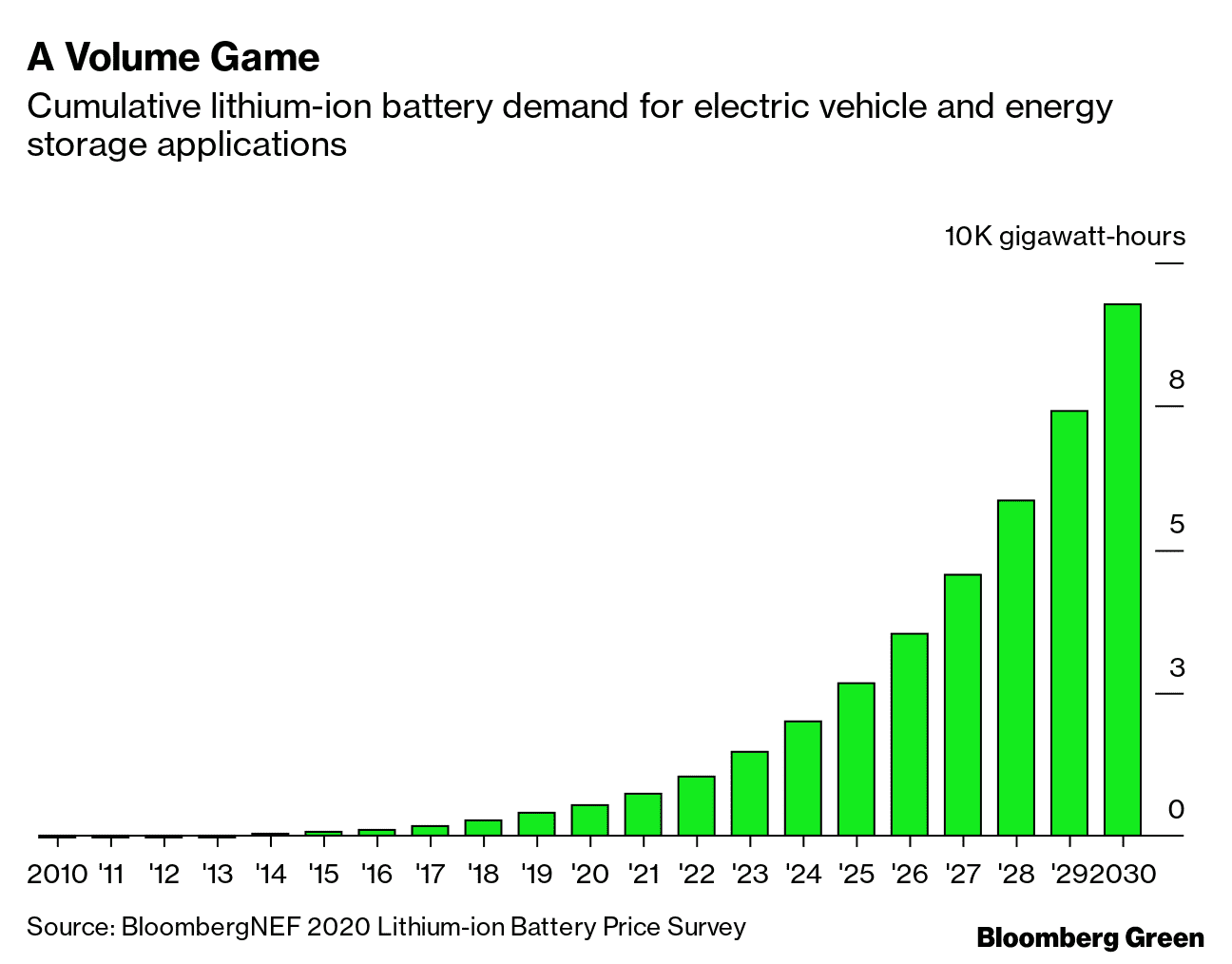

Bloomberg: “This Is the Dawning of the Age of the Battery“

Over the years, lithium-ion batteries, widely used in electric vehicles (EVs) and portable devices, have increased in energy density, providing extended range and improved performance.

Emerging technologies such as solid-state batteries, lithium-sulfur batteries, and flow batteries hold potential for greater storage capacities than lithium-ion batteries.

Recent developments in battery energy density and cost reductions have made EVs more practical and accessible to consumers. As battery technology continues to improve, EVs are expected to match or even surpass the performance of internal combustion engine vehicles, leading to a widespread adoption. Projections are that more than 60% of all vehicles sold by 2030 will be EVs, and battery technology is instrumental in supporting that growth.

Batteries also play a vital role in enhancing power-grid resilience by providing backup power during outages and improving stability in the face of intermittent solar or wind generation. Battery technologies facilitate power management by storing and releasing electricity based on grid-demand fluctuations. Battery management systems (BMS) are critical to effectively managing the battery, and artificial intelligence is increasingly being used to maximize the BMS[1].

As the demand for batteries continues to rise with the increasing adoption of electric vehicles and renewable energy systems, the development of efficient battery-recycling technology becomes crucial. In addition, alternative batteries are being developed that reduce reliance on rare earth metals. These include solid-state batteries that replace the Li-Ion battery’s liquid electrolyte with a solid electrolyte, resulting in a more efficient and safer battery.

Published in March 2020 in IEEE Power Electronics Magazine by the IEEE Power Electronics Society, the authors discuss solid-state battery prototypes in Electric Vehicle Batteries Eye Solid-State Technology: Prototypes Promise Lower Cost, Faster Charging, and Greater Safety[2].

Sodium-ion batteries are another option where sodium replaces the lithium electrolyte. As sodium is more readily available than lithium, it could significantly reduce the battery’s cost. In their paper The Research progress and comparisons between Lithium-ion battery and Sodium ion battery[3], published at the 2019 IEEE 19th International Conference on Nanotechnology by the IEEE Nanotechnology Council, the authors compare lithium-ion versus sodium-ion batteries from the aspect of economic and electrochemical performance.

In the case of stationary grid storage, 2030.2.1 – 2019, IEEE Guide for Design, Operation, and Maintenance of Battery Energy Storage Systems, both Stationary and Mobile, and Applications Integrated with Electric Power Systems[4] provides alternative approaches for design and operation of stationary and mobile battery energy storage systems.

In addition to gaining efficiencies in battery technology, closed-loop systems provide a new approach to battery recycling that conserves valuable resources as well as minimizes hazards associated with improper disposal. Techniques such as hydrometallurgical[5] and pyrometallurgical methods are employed to extract and separate valuable metals like lithium, cobalt, nickel, and manganese from spent batteries. These processes involve crushing, shredding, mechanical separation, or leaching to recover reusable materials.

The recycled materials are then utilized to manufacture new batteries, creating a closed-loop or circular process. In doing so, manufacturers can reduce their dependence on rare-earth raw materials and minimize energy consumption associated with the production of new batteries. For example, batteries retired from electric vehicles can find new uses in stationary energy storage applications, maximizing their lifecycle. In their paper, A Road Map to Sustainable Mobility: Analyzing the Dynamics of Lithium-Ion Battery Recycling[6], published as part of the 2021 IEEE Transportation Electrification Conference by the IEEE Transportation Electrification Community, the authors report on their study of recycling EV lithium-ion batteries to be repurposed as stationary storage applications for renewal energy production.

Through advanced technologies, including implementing artificial intelligence and data analytics, and efficient closed-loop systems, innovative battery technology will drive the transition to a clean tech energy future.

[1] Yong-Jia, L., Ting, L. and Gui-sheng, Z. (2011). Hydrometallurgical process for recovery and synthesis of LiCoO2 from spent lithium-ion batteries. [online] IEEE Xplore®. doi: https://doi.org/10.1109/ICETCE.2011.5775378

[2] Bindra, A. (2020). Electric Vehicle Batteries Eye Solid-State Technology: Prototypes Promise Lower Cost, Faster Charging, and Greater Safety. IEEE Power Electronics Magazine, [online] 7(1), pp.16–19. doi: https://doi.org/10.1109/MPEL.2019.2961203

[3] Tian, W., Li, M., Niu, J., Li, W. and Shi, J. (2019). The Research progress and comparisons between Lithium-ion battery and Sodium ion battery. [online] IEEE Xplore. doi: https://doi.org/10.1109/NANO46743.2019.8993684

[4] IEEE Guide for Design, Operation, and Maintenance of Battery Energy Storage Systems, both Stationary and Mobile, and Applications Integrated with Electric Power Systems. (2019). IEEE Std 2030.2.1-2019, [online] pp.1–45. doi: https://doi.org/10.1109/IEEESTD.2019.8930450

[5] Yong-Jia, L., Ting, L. and Gui-sheng, Z. (2011). Hydrometallurgical process for recovery and synthesis of LiCoO2 from spent lithium-ion batteries. [online] IEEE Xplore. doi: https://doi.org/10.1109/ICETCE.2011.5775378

[6] T V, K.M., Pratap, B., Amit, R.K. and Venugopal, S. (2021). A Road Map to Sustainable Mobility: Analyzing the Dynamics of Lithium-Ion Battery Recycling. [online] IEEE Xplore. doi: https://doi.org/10.1109/ITEC-India53713.2021.9932513